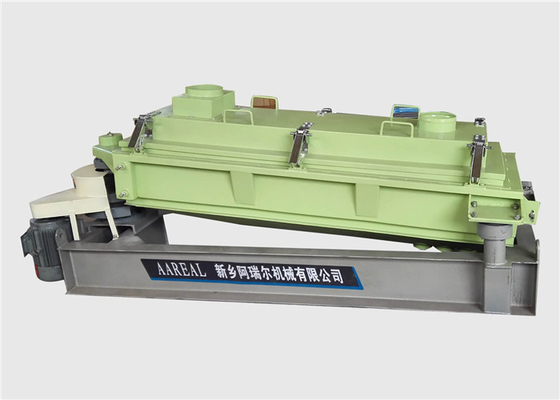

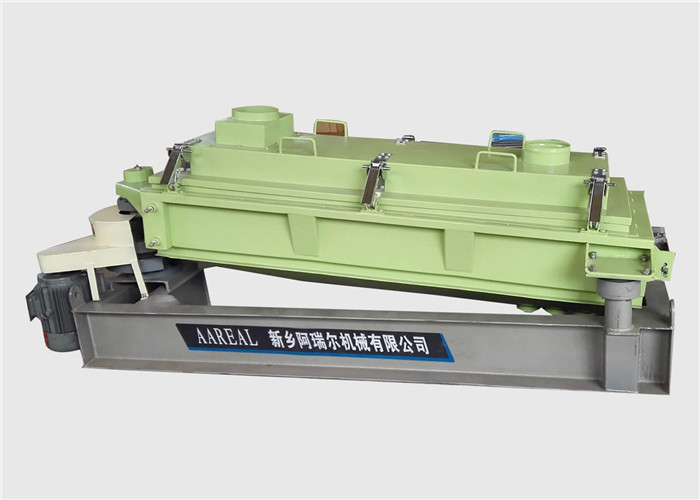

Overview of High Accuracy Industrial Gyratory Screen Separators for Catalyst Catalyzer:

High Accuracy Industrial Gyratory Screen Separators for Catalyst Catalyzer is one of the most widely used industrial screening equipment for separation and grading of Fine material which is aiming at large capacity and high screening accuracy.

It is also well known as the gyratory screen, gyratory screener, gyratory sifter, gyratory separator, gyratory screening machine, Rotex screen, Rotex screening machine, Rotex separator, planar rotary screen, plane rotary screen, rotary flat sieve, flat screen, square precision screening machine, reciprocating screen etc.

| Moving Trajectory |

gyratory reciprocating motion: circular motion at feed end, elliptical motion at center, and linear motion at discharge end |

| Drive Device |

general motor + pulley belt + exciter |

| Layers of Screen |

1~4 layers of screen available (suggest 1~3 layers) |

| Screen Size |

500*1500mm, 1000*2100mm, 1000*3000mm, 1200*3600mm, 1500*3000mm, 1500*3600mm, 1800*3600mm, 1800*4000mm, 2000*5000mm etc. |

| Motor Brand |

Siemens, or according to customer requirements |

| Spare Parts |

the special screen, drive exciter, compensating clamps and clips are made by ourselves |

| Discharge Port |

usually at the bottom of the machine, it can also be made at the back of the machine (the outlet is above the drag link) |

| Material |

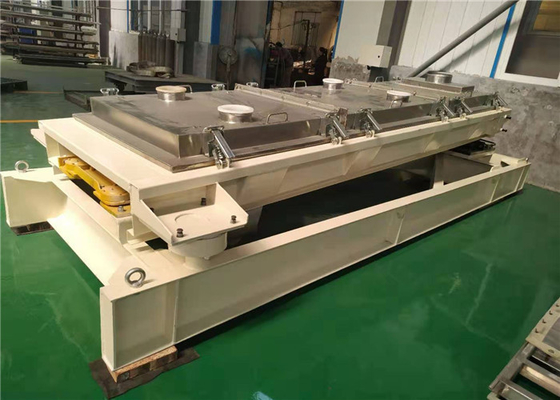

carbon steel, stainless steel, aluminium (optional) |

| Installation |

cable suspension installation, floor seat installation |

| Mesh Cleaning Method |

Use positive bounce balls to clean the screen mesh. Rubber ball, silicone ball, polyurethane ball etc. |

Working Principle of High Accuracy Industrial Gyratory Screen Separators for Catalyst Catalyzer:

AAREAL's AD model gyratory screen separator is driven by an general motor. This gyratory screening machine drives the eccentric wheel to do gyratory reciprocating motion.

The gyratory reciprocating motion gradually transitions along the length of the machine, starting off as purely gyratory motion at the inlet, then moving to elliptical movement in the middle and reverting back to reciprocating toward the outlet.

1. Circular motion at feed end:

Spreads the material across the full width of the screen surface;

Stratifies the material;

Aggressively conveys material forward.

2. Changing to elliptical motion at center:

Long-stroke elliptical action;

Enhances product stratification;

Conveys material at high capacity.

3. Reciprocating motion at discharge end:

Removes near-size particles;

Improves screening efficiency;

No vertical component ensures material is in constant contact with the screen surface.

Advantages of High Accuracy Industrial Gyratory Screen Separators for Catalyst Catalyzer:

1. Eliminates Screen Blinding

Through the use of our mesh cleaning balls and Gyratory Reciprocating Motion, material blinding is virtually nonexistent.

2. Longevity and Durability

The gyratory screen machine drives are designed for long-term, trouble-free service with minimal maintenance.

3. Increased Screening Performance

All of the gyratory sifter machines deliver greater efficiencies, superior particle accuracies and higher yields.

4. Consistent Screen Tension

The screen is automatically tensioned with each new installation through the use of our unique screen-attachment method.

Technical Parameters of High Accuracy Industrial Gyratory Screen Separators for Catalyst Catalyzer:

|

Layers

|

Model |

Screen Surface Specification (W*L) (mm) |

Screen Box Stroke (mm) |

Motor |

A

(mm)

|

B

(mm)

|

C

(mm)

|

D

(mm)

|

Weight

(kg)

|

|

Power

(kw)

|

Rotation Rate (rpm) |

| 1 |

AD-1014-1 |

1000*1400 |

63.5 |

1.5 |

960 |

2731 |

962 |

1168 |

1200 |

715 |

| AD-1021-1 |

1000*2100 |

63.5 |

1.5 |

960 |

3285 |

962 |

1156 |

1200 |

980 |

| AD-1030-1 |

1000*3000 |

63.5 |

1.5 |

960 |

4484 |

1035 |

1194 |

1251 |

1200 |

| AD-1521-1 |

1500*2100 |

63.5 |

1.5 |

960 |

3460 |

1003 |

1708 |

1759 |

1380 |

| AD-1530-1 |

1500*3000 |

76 |

2.2 |

960 |

4232 |

1362 |

1778 |

1892 |

1340 |

| AD-1536-1 |

1500*3600 |

76 |

5.5 |

960 |

5098 |

1352 |

1956 |

2048 |

2410 |

| 2 |

AD-1236-2 |

1200*3600 |

76 |

5.5 |

960 |

5263 |

1327 |

2464 |

2556 |

2020 |

| AD-1021-2 |

1000*2100 |

63.5 |

1.5 |

960 |

3743 |

1121 |

1308 |

1378 |

1400 |

| AD-1030-2 |

1000*3000 |

76 |

4 |

960 |

4575 |

1317 |

1270 |

1546 |

1840 |

| AD-1521-2 |

1500*2100 |

63.5 |

4 |

960 |

3728 |

1330 |

1781 |

1946 |

1710 |

| AD-1836-2 |

1800*3600 |

76 |

7.5 |

960 |

5305 |

1500 |

2256 |

2459 |

3880 |

| AD-1530-2 |

1500*3000 |

76 |

7.5 |

960 |

4765 |

1397 |

1956 |

2159 |

2780 |

| AD-1536-2 |

1500*3600 |

76 |

7.5 |

960 |

5365 |

1368 |

2032 |

2019 |

3180 |

|

3

|

AD-1021-3 |

1000*2100 |

63.5 |

5.5 |

960 |

4854 |

1422 |

1435 |

1549 |

2150 |

| AD-1530-3 |

1500*3000 |

76 |

5.5 |

960 |

4765 |

1391 |

1956 |

2159 |

3200 |

| AD-1836-3 |

1800*3600 |

76 |

7.5 |

960 |

5200 |

1500 |

2400 |

2500 |

4170 |

| AD-2050-3 |

2000*5000 |

92 |

11 |

960 |

5400 |

2000 |

2750 |

2810 |

5500 |

Installation of High Accuracy Industrial Gyratory Screen Separators for Catalyst Catalyzer:

1. Floor Mounting:

The gyratory screen machine counterbalanced drive has low transmitted forces, so it can be floor-mounted in properly designed structures, a design feature unique to this type of equipment. The gyratory sifter can be mounted directly on the floor or on an elevated structural steel framework, which allows for drums and other equipment to be located under the machine.

Forward Type

Direct Discharge Type

2. Cable Suspension:

Our gyratory screener machine can be cable-suspended from the four corners of the machine, thereby isolating screening forces from the surrounding structure. Accurate counterbalancing of the AD model gyratory separator makes this type of installation option possible. If the existing overhead structure is not suitable or structurally unable to support the cable-suspended unit, the gyratory sifter can be suspended from a floor-mounted cable support stand. As with conventional cable suspension, this option effectively isolates the horizontal out-of-balance screening forces, which minimizes costs for new structures and permits the use of older structures that might not otherwise support cable-suspended equipment.

Cable Suspension Type

Application of High Accuracy Industrial Gyratory Screen Separators for Catalyst Catalyzer:

1. Food industry: sugar powder, starch, salt, rice, milk powder, egg -powder, sauce, syrup.

2. Chemical industry: resin, pigment, industrial medicine, cosmetic, coatings, medicine powder, granules.

3. Metallurgy, Mining industry: aluminum powder, copper powder, ore alloy powder, welding rod powder.

4. Waste treatment: disposed oil, disposed water, disposed dye waste water, active carbon.

5. Medical industry: all kinds of medicine.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!