High Efficiency Crushing And Grinding Equipment For Aluminium Magnesium Hydroxide

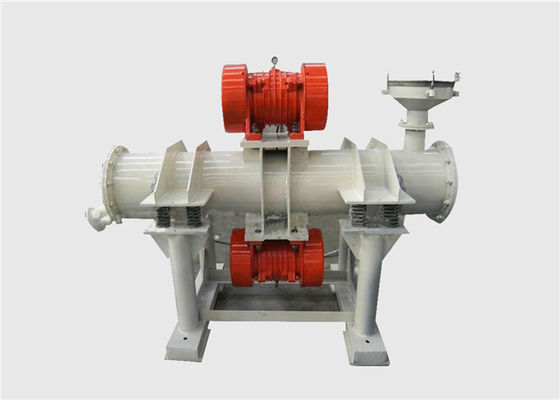

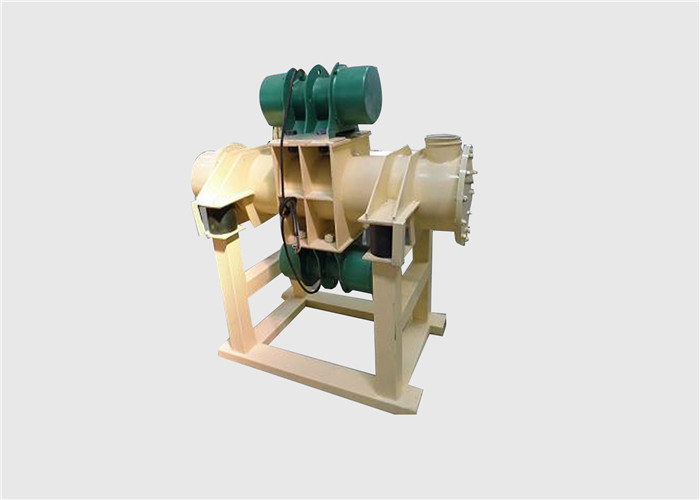

Introduction of Vibration Mill Grinding Equipment for Aluminium Magnesium Hydroxide:

ZM series Vibration Mill Grinding Equipment for Aluminium Magnesium Hydroxide is an efficient grinding equipment in grinding fine and super fine powder material,it is of high efficiency and low energy consumption,the structure is reasonable and compact, the machine is easy to install and maintain.it is widely popular with customers.

Structure of Vibration Mill Grinding Equipment for Aluminium Magnesium Hydroxide:

The energy-saving single cylinder vibration mill for grinding powder is mainly composed of vibrating motor, body, chassis, grinding cylinder, liner, grinding medium and elastic support etc.

1. Vibrating motor: providing energy for the vibration grinding of the mill. The vibrating motor has two sets of eccentric blocks, and the eccentric blocks on both sides rotate in the same direction, so that the required exciting force tick marks are aligned with the datum line of the shaft end.

2. Chassis: lifting the body by elastic support.

3. Grinding cylinder housing: It is the working body of the vibration mill, which is used to hold the grinding medium and the grinding material. The grinding cylinder housing is composed of a grinding cylinder, and the grinding cylinder is equipped with a wear-resistant lining cylinder. When the lining cylinder is ground and damaged, it can be removed and replaced.

4. Lining cylinder: it is closely attached to the inner wall of the grinding cylinder to protect the grinding cylinder. When the material is vibrated in the grinding cylinder, the inner wall of the grinding cylinder is also greatly worn at the same time, and the liner which is easy to replace in the grinding cylinder can improve the service life of the whole machine.

5. Grinding medium: it is the grinding main body of the mill, which is used for impact grinding of materials.

6. Elastic support: installed on four fulcrums, each fulcrum has two springs, the main function is to make the mill body in an elastic state, and basically isolate the vibration impact on the base when the body vibrates, thereby reducing the dynamic load transferred by the mill to the foundation. In order to keep the mill in good working condition, the gasket can be adjusted under the spring support, which is used to solve the installation problem of the levelness of the grinding body (cylinder). Each set of springs must ensure the coaxiality of the upper and lower contact surfaces of the spring during the installation process, and the tolerance shall not exceed 2mm.

Advantages of Vibration Mill Grinding Equipment for Aluminium Magnesium Hydroxide:

1. Easy installment and maintenance.

2. Low energy consumption and low production cost.

3. Closed milling system, no dust emission, no pollution.

4. Perfect electrical control function, very convenient for switching system.

5. Simple production process and high efficiency.

Technical Parameters of Vibration Mill Grinding Equipment for Aluminium Magnesium Hydroxide:

|

Model

|

Motor

|

Power (kw)

|

Cylinder Volume (L)

|

Capacity (kg/h)

|

Feeding Particle Size (mm) |

Discharge Particle Size (mm) |

Vibration Frequency (r/min) |

Working Amplitude (mm) |

| ZM5 |

5-6 |

0.4 |

5 |

1-5 |

0-25

|

0.1-0.010

|

960 |

0-10

|

| ZM10 |

10-6 |

0.75 |

10 |

5-10 |

980

|

| ZM20 |

16-6 |

1.1 |

20 |

20-50 |

| ZM50 |

20-6 |

1.5 |

50 |

50-100 |

| ZM100 |

30-6 |

2.2 |

100 |

50-150 |

| ZM200 |

50-6 |

3.7 |

200 |

50-200 |

| ZM400 |

100-6 |

7.5 |

400 |

50-300 |

| ZM500 |

100-6 |

8.5 |

500 |

50-400 |

| ZM600 |

140-6 |

9.5 |

600 |

50-600 |

| ZM800 |

160-6 |

12 |

800 |

50-1000 |

| ZM1000 |

180-6 |

14 |

1000 |

100-1500 |

| ZM1200 |

240-6 |

18.5 |

1200 |

100-1800 |

| ZM1500 |

250-6 |

21 |

1500 |

100-2000 |

| ZM2000 |

300-6 |

25 |

2000 |

100-3000 |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!