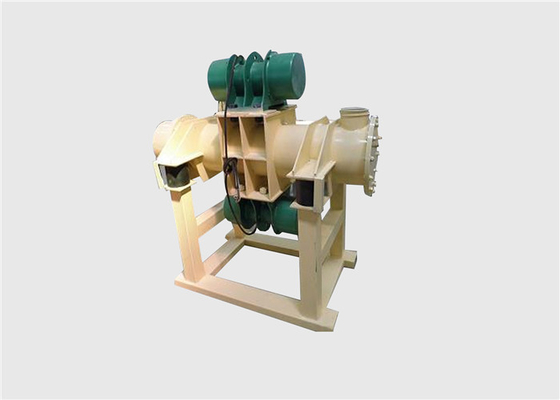

Powder Metallurgy Crushing And Grinding Equipment Vertical Double Tube

Introduction of High Efficiency Vertical Double Tube Vibrating Mill for Powder Metallurgy:

High efficiency Vertical Double Tube Vibrating Mill for Powder Metallurgy is a new type of efficient grinding equipment in grinding fine and super fine powder materials. It is more convenient than conventional rotary grinding machine (efficiency of 2-5 times, reducing energy consumption by 20% - 30%).

The vibrating mill in ultra fine grinding has various vibration strength,high efficiency ,low power consumption, less noise and compact structure, convenient installation and maintenance,etc. The grinding mill falls in with popular demands.

Some Information About High Efficiency Vertical Double Tube Vibrating Mill for Powder Metallurgy:

| Inlet and Outlet |

1. one inlet and one outlet: the grind materials will stay in the vibrating tube for long time and will be finer

2. two inlets and two outlets: has large capacity. The two tubes work independently. It feeds and discharges materials at the same time.

|

| Flexible Coupling |

usually use the belt, but will use the universal instead if the vibrating mill is big |

| Grinding Medium |

ceramic ball, stainless steel ball, manganese steel ball, manganese steel rod |

| Grinding Linings |

rigid manganese steel lining, ceramic lining, polyurethane lining |

| Springs |

rigid spring, high pressure plastic spring |

Working Principle of High Efficiency Vertical Double Tube Vibrating Mill for Powder Metallurgy:

When the power is turned on, the motor drives the exciter to rotate through the flexible coupling, generating sufficient exciting force to make the mill body enter the ring periodic vibration state, and the vibrating pendulum impact force is continuously transmitted to all the materials loaded into the grinding cylinde (i.e the medium and the material to be ground). The ground material is pulverized and ground by the mutual impact between the grinding medium and the material to be ground.

The drive motor moves around flexible coupling to rotate vibrator , and then producing enough vibrating force, then the body of the mill does periodic motion, and to continuously transfer the force to all the materials (raw materials and medium) in the roller, the material is crushed by extruding force between medium and the grinding materials .during the process We can lower down the temperature inside the mill chamber for heat sensitive material grinding. This mill is of high performance with simple process.

Application of High Efficiency Vertical Double Tube Vibrating Mill for Powder Metallurgy:

The 2ZM double tube vibrating mill can be widely used in mineral, building materials, grinding materials of powder metallurgy, electric, ceramic, refractory, magnetic material, Chemical, food, and other industries. It is the ideal substitute of ball mill.

Advantages of High Efficiency Vertical Double Tube Vibrating Mill for Powder Metallurgy:

1. Closed milling system, no dust emission, no pollution.

2. Simple production process, suitable for automatic remote controlling and switching.

3. Low energy consumption and low production cost.

4. Easy installment and maintenance.

5. Perfect electrical control function, very convenient for switching system.

6. Dry milling or wet milling are available, protective gas can be added.

Technical Parameters of High Efficiency Vertical Double Tube Vibrating Mill for Powder Metallurgy:

| Model |

2ZM-100 |

2ZM-200 |

2ZM-400 |

2ZM-800 |

2ZM-1200 |

| Grinding Method |

dry method, wet method, open circuit, closed circuit |

| Feeding Particle Sise |

0-25 mm |

| Discharge Particle Size |

0.3-0.074 mm |

| Cylinder Volume (L) |

100 |

200 |

400 |

800 |

1200 |

| Capacity (t/h) |

0.1-1.5 |

0.2-3 |

0.5-5 |

1-10 |

1-16 |

| Amplitude (mm) |

9-14 |

9-14 |

8-11 |

7-9 |

7-9 |

| Power (kw) |

17-22 |

22-37 |

45-55 |

55-75 |

75-90 |

| vibration frequency (times/min) |

16.3 |

16.3 |

16.3 |

16.3 |

16.3 |

| Weight (t) |

2.5 |

4 |

6.6 |

11.5 |

14 |

| Dimensions (L*W*H) (mm) |

2612*1654*2054 |

2900*1884*2378 |

3800*2350*24900 |

4843*2956*2510 |

|

Installation and Adjustment of High Efficiency Vertical Double Tube Vibrating Mill for Powder Metallurgy:

The motor bracket of the machine is bolted to the chassis. When installing, after leveling the frame, the body part of the mill is placed on the elastic support, and the motor shaft and the machine spindle (exciter shaft) are aligned on the same center line, and connect the flexible coupling.

The following work must be done well before the machine is turned on.

1. The sound-proof cover is installed to reduce the influence of the machine noise on the working area.

2. The motor power of this series of vibration mill is relatively large, and it is recommended to use step-down start to reduce the impact on the power grid during start-up. In general, special electric cabinet is not configured. Special requirements can be customized separately.

3. Fill in the grinding medium. No grinding medium, do not start the machine, in case that the machine is too light to cause a run-away accident.

4. Connect circulating water for cooling. Circulating water has two functions: one is to reduce the temperature during bearing operation to protect the bearing; the other is to absorb the heat generated during vibration grinding in the vibrating grinding cylinder by adding the circulating water in the jacket to the material which can not withstand the higher vibration grinding temperature.

5. According to the different grinding materials, the required vibration grinding strength is also different. For this purpose, people can increase or decrease the secondary eccentric block. When a large exciting force is required, the secondary block can be fastened and connected to the eccentric device by a bolt, otherwise, remove the secondary block.

6. If require continuous automatic feeding and continuous automatic discharging, our factory can configure automatic feeding and discharging device for users.

Structure of High Efficiency Vertical Double Tube Vibrating Mill for Powder Metallurgy:

The machine is mainly composed of a chassis, a body bracket, a soundproof cover, a machine body, a grinding cylinder, a vibration exciter, a lining plate, an elastic support, a grinding medium and a drive motor.

1. The chassis supports the body through elastic support and keeps the flexible connection distance between the driving motor and the vibrating body unchanged.

2. The soundproof cover is used to block the noise generated by the mill during operation, in order to reduce the impact of noise on the whole working area.

3. The machine body is fastened with a grinding cylinder and is equipped with a vibration exciter.

4. The grinding cylinder is the working body of the mill for grinding, which is used to hold the grinding medium and grinding material.

5. The vibration exciter is used for converting the rotating torque of the motor into the periodic vibration of the mill.

6. The lining plate is closely attached to the inner wall of the grinding cylinder to protect the grinding cylinder. When the material is vibrated in the grinding cylinder, the inner wall of the grinding cylinder is also greatly worn at the same time, and the lining plate which is easy to replace in the grinding cylinder can improve the service life of the whole machine.

7. The elastic support makes the mill body in an elastic state, and substantially isolates the vibration shock to the base when the body vibrates.

8. The grinding medium is the grinding body of the mill, and is used for impact grinding of the material.

9. The motor supplies energy to the mill for grinding.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!