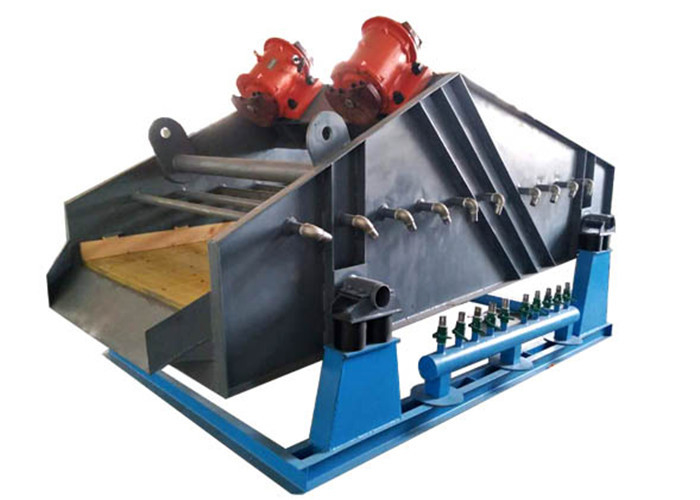

Linear Dewatering Vibrating Screen For Coal Preparation Plant Coal Classification

Introduction of Vibrating Dewatering Screen for Coal Preparation Plant Coal Classification:

Vibrating Dewatering Screen for Coal Preparation Plant Coal Classification is a large-scale screening equipment with international quality developed by our company in recent years. It is suitable for the dewatering of raw coal in coal preparation plants, classification, desliming, screening of mines, power plant screening and coal chemical industry and other new energy industry material separation process. The material is not easy to block the sieve hole. The sieve plate life is longer than the traditional round vibrating sieve. It is the first choice for the traditional round vibrating screen upgrade.

Working Principle of Vibrating Dewatering Screen for Coal Preparation Plant Coal Classification:

The dewatering screen adopts dual-motor self-synchronization technology. The motors coordinate with universal eccentric and adjustable amplitude vibrator. When the two motors start to work, the vibrators move reversely at the same time. The centrifugal forces is generated by the eccentric blocks will superpose themselves and form a single direction vibration. The high frequency vibration drives the screen move back and forth in line repeatedly. So the sand can be dehydrated and filtered.

Technical Parameters of Vibrating Dewatering Screen for Coal Preparation Plant Coal Classification:

| Model |

Screen Surface Area

(m2) |

Mesh Size

(mm) |

Screen Mesh Structure |

Feeding Size

(mm) |

Capacity

(t/h) |

Vibration Frequency

(min-1) |

Double Vibration Amplitude

(mm) |

Power

(kw) |

Vibrating Direction Angle

(°) |

Overall Size

(mm) |

| 926 |

2.34 |

0.25-50 |

Stainless steel

woven mesh

Perforated plate

Stainless steel seam welded mesh

|

≤150 |

1.5-100 |

960 |

6-10 |

2*1.5 |

45 |

2740*1340*1520 |

| 1030 |

3 |

2-120 |

8-10 |

2*2.2 |

3140*1440*1680 |

| 1230 |

3.6 |

3-180 |

8-10 |

2*2.2 |

3140*1640*1680 |

| 1540 |

6 |

5-250 |

8-12 |

2*3.0 |

4140*1940*1790 |

Note: We reserve the right to modify the above data.

Advantages of Vibrating Dewatering Screen for Coal Preparation Plant Coal Classification:

1. Adopt self-synchronized technology of waterproof and frequency-specific motor and dual-motor drive to achieve effective dewatering effect.

2. The new dry row dehydration process has less investment compared to the traditional process, simple process, small area, etc. It is convenient for system process layout.

3. Long life of wear-resistant sieve plate. Chess assembling design, convenient replacement, cost saving, sieve size can be selected according to requirements.

4. The method of riveting and welding of steel components constitutes a frame body with no internal stress, high strength, light weight and durability.

5. Professional frequency, amplitude and low power consumption design can suit a variety of dewatering needs, 24 hours continuous dry row operation, V-type screen surface design, -5' climbing surface dewatering, dry exhaust tailings low in water content, high efficiency, large capacity per unit area.

Vibration Exciter Type Vibration Motor Type

Application of Vibrating Dewatering Screen for Coal Preparation Plant Coal Classification:

Dewatering tailings

Dewatering sand

Desliming

Sand recovery

Dewatering mineral concentrates

Scalping oversize from suspensions and slurries

Some Tips When You Order Vibrating Dewatering Screen for Coal Preparation Plant Coal Classification:

1. When selecting and ordering, the user should determine the arrangement of the sieve and screen seam size. If they do not make a decision, we supply the machine according to the right-type screen seam 0.5mm arrangement. (The motor is installed on the left or right side of the material flow direction.)

2. When the forced synchronization is adopted, the motor can be installed on the left or right. User must state when ordering.

3. The screen structure (weaving, punching, wedge-bar), mesh size, processing capacity, material name and feeding particle size should be indicated in the selection and ordering by the user.

4. The dip angle of the screen surface can be adjusted from -2 to 10 degrees. Other angles can be adjusted by the user.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!