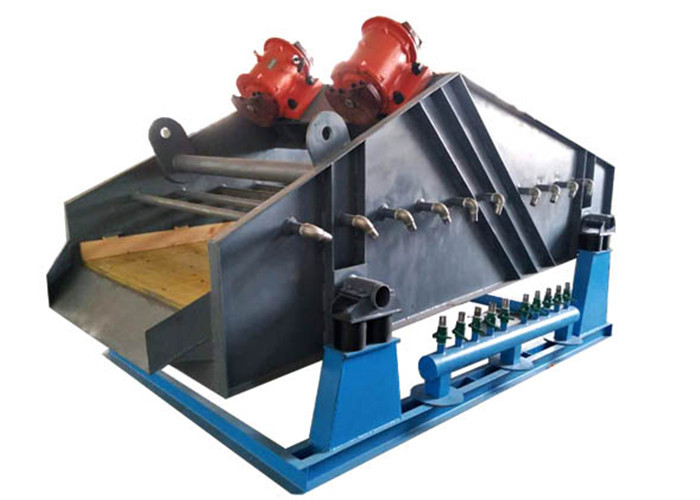

High Strength Rectangular Vibrating Screen Mining Sand Screening Machine

Introduction of High Efficiency Mining Sieving Vibrating Dewatering Screen for Sand Casting:

High Efficiency Mining Sieving Vibrating Dewatering Screen for Sand Casting are used for separation of solids from liquids. They are used in mining sector for high level screening, dewatering and draining applications of coal, gold, iron, lead, chrome, sand, etc.

Characteristics of High Efficiency Mining Sieving Vibrating Dewatering Screen for Sand Casting:

1. Waterproof Motor:

Waterproof proper frequency dedicated motor, double motor-driven self-synchronization technology , to achieve efficient of dewatering.

2. Low Cost Investment:

Compared with the traditional process, our company new-type dry-line dewatering process has the advantages of small investment, simple process and small area, which is convenient for the system process layout.

3. Continuous Dewatering Operation:

Professional design of the frequency, amplitude, low-power source for a variety of dewatering needs 24-hour continuous operation.

4. Large Capacity:

V-screen design, -5 degrees screen surface slope dewatering, dewatering screen with low water, high efficiency, large capacity per unit area.

5. Long Service Life:

High wear-resistant screen plate long life, modular assembly design, easy replacement, cost savings, screen mesh size can be selected according to requirements.

6. High Strength and Durable Structure:

Rigid-welded steel components assembly, constitute the machine body with no internal stress, high strength, light and durable.

Some Tips for High Efficiency Mining Sieving Vibrating Dewatering Screen for Sand Casting:

1. When selecting and ordering, the user should determine the arrangement of the sieve and screen seam size. If they do not make a decision, we supply the machine according to the right-type screen seam 0.5mm arrangement. (The motor is installed on the left or right side of the material flow direction.)

2. The dip angle of the screen surface can be adjusted from -2 to 10 degrees. Other angles can be adjusted by the user.

3. The screen structure (weaving, punching, wedge-bar), mesh size, processing capacity, material name and feeding particle size should be indicated in the selection and ordering by the user.

4. When the forced synchronization is adopted, the motor can be installed on the left or right. User must state when ordering.

Working Principle of High Efficiency Mining Sieving Vibrating Dewatering Screen for Sand Casting:

Dewatering screen adopt dual-electrode self-synchronization technology, universal eccentric block, adjustable amplitude vibrator. The machine is combined mainly by the screen box, exciter, support system and motor. The two mutually independent vibrators are respectively driven by the tape coupling to do synchronous reverse operation. The centrifugal force generated by two eccentric masses is superposed along the vibration direction and reversely counteracted, thereby forming a single vibration force along the vibration direction, making the screen box reciprocating linear motion.

The drainage screen, also known as high-frequency dewatering screen, changing the water surface tension of pulp through the exciting force, pulp water through the screen to become the undersize material, and fine material is blocked by the screen to form the filter layer by the vibration of the forward movement of discharge. Dewatering screen is mainly used for detailings dewatering in the mineral processing industry, coal slurry dehydration of coal preparation plant, washed quartz sand dewatering and ceramic slurry dehydration, and wet and dry classification, dehydration, removal and mud removal of medium and fine granular materials in industrial sectors such as electric power, sugar making and salt making.

Technical Parameters of High Efficiency Mining Sieving Vibrating Dewatering Screen for Sand Casting:

| Model |

Screen Surface Area

(m2) |

Mesh Size

(mm) |

Screen Mesh Structure |

Feeding Size

(mm) |

Capacity

(t/h) |

Vibration Frequency

(min-1) |

Double Vibration Amplitude

(mm) |

Power

(kw) |

Vibrating Direction Angle

(°) |

Overall Size

(mm) |

| 926 |

2.34 |

0.25-50 |

Stainless steel

woven mesh

Perforated plate

Stainless steel seam welded mesh

|

≤150 |

1.5-100 |

960 |

6-10 |

2*1.5 |

45 |

2740*1340*1520 |

| 1030 |

3 |

2-120 |

8-10 |

2*2.2 |

3140*1440*1680 |

| 1230 |

3.6 |

3-180 |

8-10 |

2*2.2 |

3140*1640*1680 |

| 1540 |

6 |

5-250 |

8-12 |

2*3.0 |

4140*1940*1790 |

Application of High Efficiency Mining Sieving Vibrating Dewatering Screen for Sand Casting:

Slime dewatering: slime dewatering;

Soil remediation: soil remediation;

Tailings dry discharge: iron tailings, gold tailings, copper tailings, vanadium tailings, lead - zinc tailings, graphite tailings;

Sewage treatment: urban sewage, industrial sewage, river sludge solid-liquid separation, sewage treatment plant filtration;

Washed sand: quartz sand, zircon sand, glass sand, building sand, casting sand, building materials sand, potassium feldspar dehydration.

Vibration Exciter Type Vibration Motor Type

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!