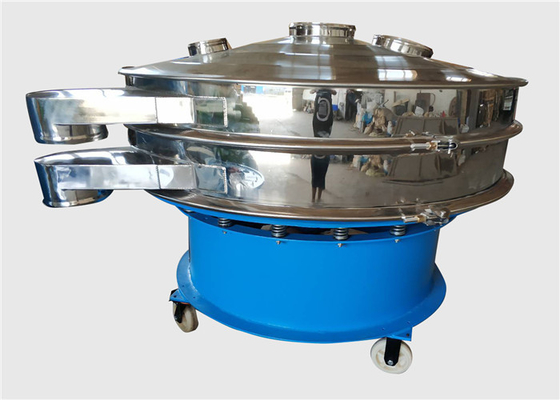

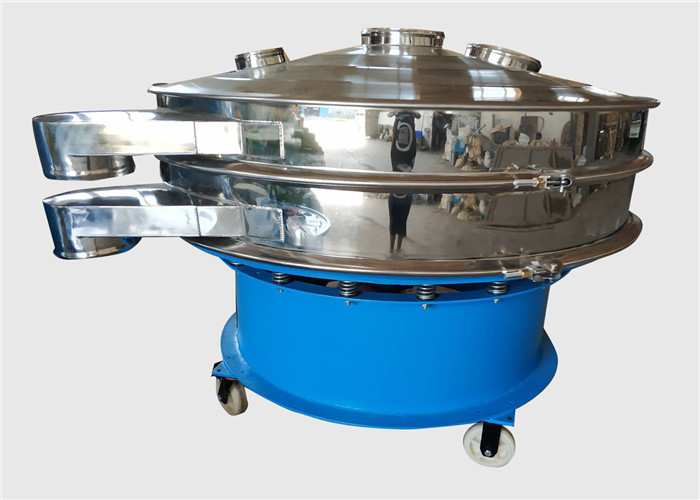

Multilayer Rotary Vibrating Screen Melamine Myrex Resin Round Separator

Introduction of Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening:

Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening can be also called circular vibrating screen, circular vibrating sieve, vibro screen, vibro sifter, rotary vibrating screen, rotary vibrating sieve, vibro sieve, vibrating separator, vibrating sifter etc. It is a kind of classic vibrating sieve machine for most materials general use.

Some Information About Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening:

| Model |

AY |

| Shape |

circular or round shape |

| Layers of Screen |

1~5 layers of screen with 2~6 outlets |

| Mesh Size |

above 325 mesh |

| Screen Frame |

adhesive type, L type (bolt insert type), ultrasonic type (transducer internal and external) etc. |

| Mesh Cleaning Method |

bouncing balls, ultrasonic system, rotary brush system etc. |

| Machine Diameter |

400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm etc. |

| Material |

stainless steel 304, 316L, carbon steel, plastic materials etc. |

| Surface Treatment |

Paint, sandblast and polish etc. |

| Function |

grading, solid-separation, remove the impurity, dewatering etc. |

| Movement |

three dimensional vibration motion |

| Damping Spring |

carbon steel spring, stainless steel spring, air spring, rubber spring etc. |

| Motor |

verticle vibrating motor |

| Motor Brand |

AAREAL Made, OLI-WOLONG, Italvibras etc. |

| APO Safety System |

Automatic Power Off Safety System is integrated in the motor |

| Spare Parts |

screen, bounce balls, clamps, springs, sealing rubber strip etc. |

| Optional Design |

discharge gate, magnetic guard, quick release clamp, glass viewing port etc. |

Structure Diagram of Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening:

Features of Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening:

1. High screening precision, high efficiency, suitable for any powder, grain and mucus materials.

2. New grid structure, long service life of screen cloth, only 3-5min for screen replacement.

3. Can be used with single or multilayer screen mesh.

4. Automatic discharge of materials, continuous operation.

5. No dead corner of parts, easy rinse thoroughly and disinfection.

6. Fully enclosed structure, no flying dust, no liquid leakage, no blocking of mesh opening, screen can reach 500 meshes, and filter can reach 5 um.

7. Small volume, less space occupation, easy to move,360 degree adjustment of discharge opening.

Basic Function of Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening:

1. Grading

Each model of vibrating sieve machine can precisely and continuously screen and separate screened products, the multi-layer type can screen and separate five groups of different particles at a time. It is suitable for dry materials.

2. Solid-liquid separation

The mixture of solid and liquid can be separated effectively by single or multi-layer type into different grade materials.

3. Remove the impurity

The model can quickly separate a few oversize or undersized particles from a quantity of materials.

Application of Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening:

1. Food Industry:

Sugar powder, starch, salt, rice flour, milk powder, soybean milk, egg powder, soy sauce, juice, tea, drink, dairy products, sweets, small food, frozen food, spices, protein, food additives, dehydrated vegetables, etc.

2. Pharmaceuticals Industry:

Active pharmaceutical ingredients, penicillin, tetracycline HCL, vitamin, powder, pharmaceutical intermediates, tablet, granule and granule, Chinese medicine medicinal slices, etc.

3. Chemical Industry:

Epoxy resin, resin, rubber additives, desiccant, accelerant, fluorescent whitening agent, paint, phenolic resin, polyethylene powder particles, EPS, PVC, catalyst, blowing agent etc.

4. Powder Metallurgy Industry

Iron powder, copper powder, molybdenum powder, tungsten powder, silver powder, aluminium.

5. Other Industries

Magnetic materials, lithium iron phosphate, cobalt acid lithium, graphite powder, laundry detergent, activated carbon, starch glue, glass fiber, feldspar, white corundum, quick lime, mica, polishing powder, refractory material, kaolin, carbon acid calcium, quartz sand, paper, etc

Working Principle of Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening:

The rotary vibrating sifter uses the verticle vibrating motor as the source of vibration, equipped eccentricity hammer on the both sides of motor, change circumrotate to level, upright and incline movement, then pass these three movement to the surface of the screen. Adjust the phasic angle on the both sides of the top and bottom to change the movement orbits of the surface screen.

The general characteristics of the vibrator adjustment are described below:

Technical Parameters of Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening:

| Model |

Power |

Screen Surface Diameter |

Effective Screening Area (m2) |

Layers of Screen |

| AY-400 |

0.18 KW |

350mm |

0.0962 |

1~3 |

| AY-600 |

0.25 KW |

550mm |

0.2375 |

1~3 |

| AY-800 |

0.55 KW |

750mm |

0.4416 |

1~3 |

| AY-1000 |

0.75 KW |

920mm |

0.6644 |

1~3 |

| AY-1200 |

1.1 KW |

1120mm |

0.9847 |

1~3 |

| AY-1500 |

1.5 KW |

1420mm |

1.5829 |

1~3 |

| AY-1800 |

2.2 KW |

1720mm |

2.3223 |

1~3 |

| AY-2000 |

3.0 KW |

1920mm |

2.89 |

1~3 |

Overall Dimensions of Multilayer Rotary Vibrating Sieve Machine for Melamine Myrex Resin Screening:

| Model |

A |

B |

C |

D |

E |

F |

G |

I |

Single Layer Height |

Double Layer Height |

Three

Layer

Height

|

| AY-400 |

472 |

372 |

150 |

400 |

110 |

60 |

300 |

270 |

550 |

660 |

770 |

| AY-600 |

570 |

450 |

200 |

600 |

120 |

80 |

380 |

340 |

730 |

865 |

1000 |

| AY-800 |

690 |

570 |

200 |

800 |

130 |

100 |

550 |

340 |

730 |

865 |

1000 |

| AY-1000 |

810 |

690 |

250 |

970 |

150 |

120 |

650 |

400 |

790 |

925 |

1060 |

| AY-1200 |

970 |

850 |

250 |

1170 |

180 |

130 |

760 |

450 |

860 |

1025 |

1190 |

| AY-1500 |

1180 |

1060 |

250 |

1470 |

200 |

140 |

950 |

480 |

985 |

1180 |

1370 |

| AY-1800 |

1480 |

1360 |

350 |

1770 |

220 |

150 |

1110 |

520 |

1030 |

1220 |

1410 |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!