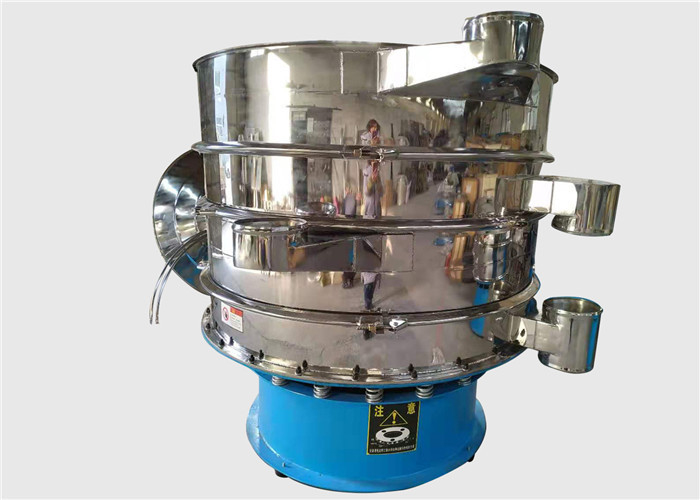

Introduction of Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry is a self-contained equipment working on the principle of rotary motion using low powered motor. rotary vibrating screen separates bulk solid materials from solids and slurries, utilizing multi-plane, inertial vibration that causes particles to pass through apertures in the screen or to travel across the screen surface in controlled pathways.

1. rotary vibrating filter sieve machine handles dry/wet screening of particles from 30mm down to 500 mesh in size.

2. rotary vibrating sieve ranges in diameter from 400mm to 2000mm, with single or multiple screening decks (up to five).

Features of Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

1. Simple and functional design - higher capacity, easy use, less maintenance, lower noise, and require minimal floor space.

2. Anti-binding devices - prevent screen clog without creating dust clouds during operations.

3. Automatic discharge of separated materials - continuous and uninterrupted production.

4. Light weight - easily movable with pellet jack or forklift.

5. Simple and functional design – higher capacity, easy use, less maintenance, lower noise, and require minimal floor space.

6. Lower energy consumption – reduce cost.

7. Stainless Steel - all contact parts in stainless steel SS304. Full or partial SS316L upgrades available.

8. Wide range of sizes and modifications available to suit all types of powder and viscous liquids.

9. Quick change design - allows screen change in less than 5 minutes.

10. Up to 5 screens per unit - allowing multiple separations with just one unit for cost effective operation.

11. Lower energy consumption - reduce cost.

12. Highly durable - designed for long hours of operation with minimal service required.

Important Information About Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

| Model |

AY |

| Shape |

circular or round shape |

| Layers of Screen |

1~5 layers of screen with 2~6 outlets |

| Mesh Size |

above 325 mesh |

| Screen Frame |

adhesive type, L type, ultrasonic type (transducer internal and external) etc. |

| Mesh Cleaning Method |

bouncing balls, ultrasonic system, rotary brush system etc. |

| Machine Diameter |

400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm etc. |

| Material |

stainless steel 304, 316L, carbon steel etc. |

| Function |

grading, solid-separation, remove the impurity etc. |

| Movement |

three dimensional vibration motion |

| Damping Spring |

carbon steel spring, stainless steel spring, air spring, rubber spring etc. |

| Motor |

verticle vibrating motor |

| Motor Brand |

China Made, OLI-WOLONG or other brand |

| Optional Design |

magnetic guard, quick release clamp, discharge gate, glass viewing port etc. |

Structure Diagram of Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

Basic Function of Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

1. Remove the impurity

The model can quickly separate a few oversize or undersized particles from a quantity of materials.

2. Solid-liquid separation

The mixture of solid and liquid can be separated effectively by single or multi-layer type into different grade materials.

3. Grading

Each model of vibrating sieve machine can precisely and continuously screen and separate screened products, the multi-layer type can screen and separate five groups of different particles at a time. It is suitable for dry materials.

Technical Parameters of Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

| Model |

Power |

Screen Surface Diameter |

Effective Screening Area (m2) |

Screen Decks |

| AY-400 |

0.18 KW |

350mm |

0.0962 |

1~3 |

| AY-600 |

0.25 KW |

550mm |

0.2375 |

1~3 |

| AY-800 |

0.55 KW |

750mm |

0.4416 |

1~3 |

| AY-1000 |

0.75 KW |

920mm |

0.6644 |

1~3 |

| AY-1200 |

1.1 KW |

1120mm |

0.9847 |

1~3 |

| AY-1500 |

1.5 KW |

1420mm |

1.5829 |

1~3 |

| AY-1800 |

2.2 KW |

1720mm |

2.3223 |

1~3 |

| AY-2000 |

3.0 KW |

1920mm |

2.89 |

1~3 |

Overall Dimensions of Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

| Model |

A |

B |

C |

D |

E |

F |

G |

I |

Single Layer Height |

Double Layer Height |

Three

Layer

Height

|

| AY-400 |

472 |

372 |

150 |

400 |

110 |

60 |

300 |

270 |

550 |

660 |

770 |

| AY-600 |

570 |

450 |

200 |

600 |

120 |

80 |

380 |

340 |

730 |

865 |

1000 |

| AY-800 |

690 |

570 |

200 |

800 |

130 |

100 |

550 |

340 |

730 |

865 |

1000 |

| AY-1000 |

810 |

690 |

250 |

970 |

150 |

120 |

650 |

400 |

790 |

925 |

1060 |

| AY-1200 |

970 |

850 |

250 |

1170 |

180 |

130 |

760 |

450 |

860 |

1025 |

1190 |

| AY-1500 |

1180 |

1060 |

250 |

1470 |

200 |

140 |

950 |

480 |

985 |

1180 |

1370 |

| AY-1800 |

1480 |

1360 |

350 |

1770 |

220 |

150 |

1110 |

520 |

1030 |

1220 |

1410 |

Optional Designs for Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

1. The APO Safety System (Automatic Power Off Safety System) is integrated in the motor. In case of short circuit, phase loss, electric leakage and unstable voltage, the motor can cut off the power automatically to safeguard the machine and your staff.

2. Discharge Gate: it is used to control production flow and speed. This enables a better flow and provides consistent discharge characteristics from even surfaces. However, the discharge rate might differ from the ratio and diameter of the discharge pipe.

3. Customised Dust Cover: it is used to reduce any leaks from the machine. It also helps reduce airborne dust from flowing on the steam or conveyer belt. This device is made custom to fit your production line.

4. Quick Release Clamp: it is used for releasing camps rings without the need to use tools. While the other side of the clamp is used for tightening. It is mostly used for cleaning and dissembling purposes.

5. Magnetic Guard: it is used for preventing any contamination and also to ensure that manufacturing is done safely and free from any irregularities. It captures particles with the use of high magnetic strength. The collected contaminants are then unleashed into the discharge chutes.

6. Spring Dust Cover: it is used to provide additional protection against dust and other particles by the strength of the springs, which is determined by the rollers which are also spring-loaded.

Working Principle of Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

The multilayer rotary vibrating sieve sifter separator machine adopts the latest vertical vibrating motor, which produces a horizontal, vertical and oblique vibration of three dimensional, and then directly passes the vibration to screen surface. Changing the angle of the upper and lower eccentric block of the motor, it produces different exciting force, and the direction in which the material is running is changed.

The rotary vibrating screen filter sieve machine is made up of spring buffer, base, upper and lower heavy hammer,vibrating motor, screen frame, clamp ring, vibrating body, inlet and outlet port, dust proof cover and other parts. The exciting force will generate by the rotation of vibrating motor. The exciting force drives the vibrating body to vibrate. So the materials on the screen cloth can shake to reach the objective that filters different grade materials., The adjustable eccentric hammer is driven to the center line through the motor, caused centrifuged force under the state of unbalance and so that the materials from regular spiral. Speed and track of materials on the screen can be controlled by adjusting the angle of the two eccentric weights.

The general characteristics of the vibrator adjustment are described below:

Application of Paper Pulp Rotary Vibrating Filter Sieve Machine Used In Papermaking Industry:

1. Chemical Industry: colophony, dope, industry leechdom, cosmetic, paint

2. Food Industry: sugar, amylum, rice powder, milk powder, soyabean milk, angel cake, sauce, juice.

3. Grinding Materials And china Industry: quartz, slurry, kaoline, carborundum, alumina, sprayer dust.

4. Metallurgy, Mining Industry: aluminum powder, welding rod powder, dioxide manganese, electrolyze copper powder, ceruse, copper powder, ore alloy powder, electromagnetic material, rubbing powder, fire-proof material, kaoline, lime, heavy calcium carbonate.

5. Paper-Making Industry: dope,white soil slurry, black and white liquid, disposed liquid, paper-making liquid and waste water recycling.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!