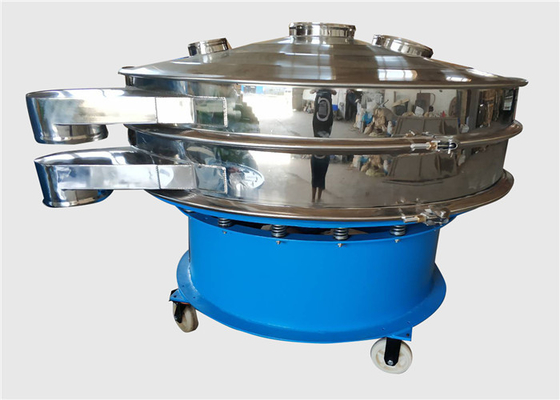

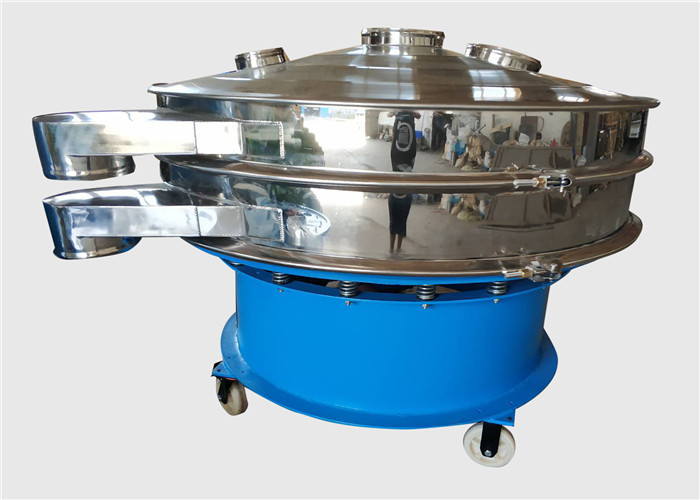

Classical Vibrating Sieve Separator Powder Coating Vibration Separation Machines

Overview of Classical Rotary Vibro Shifter For Powder Coating And Coating Powders:

The multi-deck three dimensional vibro shifter for powder coating and coating powders is also called vibro screen, viibro sifter, vibro sieve, rotary vibrating screen, rotary vibrating sieve, round separator, round vibro sieve, gyro screen, gyro sieve, round sifter, round screener, round vibro sieve machine, round gyratory screen, rotary screen, rotatory vibrating screen, rotary vibrating sieve, vibrating sifter, circular vibratory screen, circular vibrating screen, circular vibrating sieve, gyro screen, gyro sifter, gyratory sifter, gyratory screen, gyratory sieving machine, vibro separator, vibro grader, classic separator, vibratory separator, vibratory sifter, sanitary separators, filter sieve machine, industrial sifter etc.

The AY model rotary vibrating sifter is a kind of high precision powder sieving machine. By means of the upper and lower hammer mounted on the vibration motor, the sifter can turn the rotary motion force of the motor into three-dimensional motion (horizontal, vertical, inclined). Then this motion will be delivered to the screen surface. Thus, the sifter realizes the purpose of sieving. This series of vibrating sifters can be used to classify, grading and filtering in food, chemical, metal, mining and other industries.

Important Information You May Concern About Classical Rotary Vibro Shifter For Powder Coating And Coating Powders:

| Model |

AY |

| Shape |

round |

| Layers of Screen |

1~5 screen decks |

| Mesh Size |

above 325 mesh |

| Screen Frame |

L type, adhesive type, ultrasonic type etc. |

| Mesh Cleaning Method |

bouncing balls, ultrasonic system, rotary brush system etc. |

| Diameter |

400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm |

| Material |

carbon steel, stainless steel 304, 316L etc. |

| Function |

grading, solid-separation, remove the impurity etc. |

| Movement |

three dimensional vibration motion |

| Damping Spring |

galvanized steel spring etc. |

| Motor |

verticle vibrating motor |

| Motor Brand |

China Made, OLI-WOLONG etc. |

Working Principle of Classical Rotary Vibro Shifter For Powder Coating And Coating Powders:

The ratory vibrating screen has vertical type motor as excitation source, and the motor has eccentric block at the top and bottom which makes the rotating of motor convert horizontal, vertical and inclined three- dimensional motion. Then the motor pass the motion into screen mesh and make the material diffuse outward gradually. Because of that, we call it round vibrating screen machine. The round vibrating screen has the advantage of long running track and high-usage screen. Adjust the phase angle of eccentric block can change the motion track to separate the material precisely.

After starting, the eccentric block at the top and bottom of motor will generate a composite inertial force which force the screen rotary moving. The vibrating screen frame make reciprocating motion continuously under the shaking of motor and forward the screen mesh move cycling. The material on screen mesh made directional movement with screen box. In the process of moving, the material smaller than mesh size pass the mesh and fall to the under layer which called undersize, and the material bigger than mesh size separated through outlet, then the separating is completed. The function and running track of round vibrating screen as follows.

The general characteristics of the vibrator adjustment are described below:

Structure Diagram of Classical Rotary Vibro Shifter For Powder Coating And Coating Powders:

Features of Classical Rotary Vibro Shifter For Powder Coating And Coating Powders:

1. Up to 5 times output per unit area; accurately to 6 Level separation, sieving efficiency is higher than 95%.

2. We use excellent silicon rubber balls ,ultrasonic wave or rotating brush for cleaning sieving mesh. No mesh blocking.

3. Acceleration is five times less than the normal vibrating screen. Spare parts will have longer life. Thus reduce the maintain cost.

4. Noise is lower than 75 decibel. Lower foundation dynamic load.

5. Specially used for sieving high value-added products. Thus improve the profit.

Application of Classical Rotary Vibro Shifter For Powder Coating And Coating Powders:

1. Chemical industry: resin pigment, medicine, grease, paint, palette, cosmetic etc.

2. Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice etc.

3. Abrasive material and ceramic industry: building sand, mica, alumina, abrasive,refractory material, slurry etc.

4. Mining industry: kaolin, alumina, carbon, quartz sand,titanium oxide, zinc oxide etc.

5. Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation etc.

6. Mechanical industry: casting sand, powder metallurgy, electromagnetic material and metal powder etc.

7. Metallurgy industry: aluminum powder, lead powder, copper powder, ore, alloy powder ,electrode powder, manganese dioxide, electrolytic copper powder, electric magnetic material, polishing powder, refractory material etc.

8. Pollution treatment: waste oil, waste water,additives, activated carbon etc.

Basic Function of Classical Rotary Vibro Shifter For Powder Coating And Coating Powders:

1. Grading

Each model of vibrating sieve machine can precisely and continuously screen and separate screened products, the multi—layer type can screen and separate five groups of different particles at a time. It is suitable for dry materials.

2. Solid-liquid separation

The mixture of solid and liquid can be separated effectively by single or multi-layer type into different grade materials.

3. Remove the impurity

The model can quickly separate a few oversize or undersized particles from a quantity of materials.

Technical Parameters of Classical Rotary Vibro Shifter For Powder Coating And Coating Powders:

| Model |

Power |

Screen Surface Diameter |

Effective Screening Area (m2) |

Layers |

| AY-400 |

0.18 KW |

350mm |

0.0962 |

1~3 |

| AY-600 |

0.25 KW |

550mm |

0.2375 |

1~3 |

| AY-800 |

0.55 KW |

750mm |

0.4416 |

1~3 |

| AY-1000 |

0.75 KW |

920mm |

0.6644 |

1~3 |

| AY-1200 |

1.1 KW |

1120mm |

0.9847 |

1~3 |

| AY-1500 |

1.5 KW |

1420mm |

1.5829 |

1~3 |

| AY-1800 |

2.2 KW |

1720mm |

2.3223 |

1~3 |

| AY-2000 |

3.0 KW |

1920mm |

2.89 |

1~3 |

Overall Dimensions of Classical Rotary Vibro Shifter For Powder Coating And Coating Powders:

| Model |

A |

B |

C |

D |

E |

F |

G |

I |

Single Layer Height |

Double Layer Height |

Three

Layer

Height

|

| AY-400 |

472 |

372 |

150 |

400 |

110 |

60 |

300 |

270 |

550 |

660 |

770 |

| AY-600 |

570 |

450 |

200 |

600 |

120 |

80 |

380 |

340 |

730 |

865 |

1000 |

| AY-800 |

690 |

570 |

200 |

800 |

130 |

100 |

550 |

340 |

730 |

865 |

1000 |

| AY-1000 |

810 |

690 |

250 |

970 |

150 |

120 |

650 |

400 |

790 |

925 |

1060 |

| AY-1200 |

970 |

850 |

250 |

1170 |

180 |

130 |

760 |

450 |

860 |

1025 |

1190 |

| AY-1500 |

1180 |

1060 |

250 |

1470 |

200 |

140 |

950 |

480 |

985 |

1180 |

1370 |

| AY-1800 |

1480 |

1360 |

350 |

1770 |

220 |

150 |

1110 |

520 |

1030 |

1220 |

1410 |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!