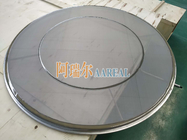

1200mm Single-layer Stainless Steel Ultrasonic Vibrating Screen for Powder Coating

Our client require a Single-layer Stainless Steel Ultrasonic Vibrating Screen, diameter 1200mm, mesh size 120 mesh (0.125mm). They use this ultrasonic vibrating separator for screening Powder Coating.

Differences in Design:

| Item Compared |

External Transducer |

Built-in Transducer |

| Installing Form |

The external transducer is mounted outside the screen frame and the extending part is at the edge of the grid |

The built-in transducer is fixed directly in the middle of the grid |

| Cleaning Method |

Disassembly and cleaning are relatively convenient |

When cleaning, people need to remove the screen frame, and then lift the grid to clean up |

| Applicable Materials |

The external transducer does not have direct contact with the material, so it can protect the transducer effectively, improving the service life, screening accuracy and output |

The built-in transducer will contact the material during use.

For some conductive and corrosive materials, contact with the transducer will reduce the service life, and also affect the output frequency, thereby reduce the precision and output.

|

Ultrasonic screen frame and ultrasonic system are two key devices of ultrasonic vibrating screen. The ultrasonic vibrating sieve adopts adhesive type screen frame. Then how to glue the screen mesh onto the frame when replacing a new screen?

The left photo shown above is the use of special tooling to stick the screen to the frame. We can supply people such tool if they ask for it. And the right photo above is the finished Ultrasonic Screen Frame or Screen Holder (transducer external type). In addition, there are transducer built-in type ultrasonic screen frame.

AAREAL ultrasonic system consists of generator, transducer, energy conducting ring, connecting nut and connecting wire. Voltage 220V/Single-phase/50HZ, working frequency 35KHz, Max. working current 0.5A.

The motor power for our 1200mm ultrasonic vibrating screen is 1.5KW, sufficient power. We will not use false motor power to deceive our customers.

Overview of Ultrasonic Vibrating Screen for Powder:

Ultrasonic vibrating screen is also called ultrasonic separator, ultrasonic vibrating sieve, ultrasonic sieve deblinding system, ultrasonic screener, ultrasonic screen separator etc.

Ultrasonic vibrating screen solves the screening problem of materials with strong adsorption, easy agglomeration, strong viscosity, high static electricity, high density, super fine powder etc. The screening accuracy can be increased by 1~100%, and the output can be increased by 1~10 times, really meeting the industrialization production of 100 mesh ~500 mesh and above.

It can be installed in various kinds of screening machines, such as ultrasonic test sieve shaker, ultrasonic round separator, ultrasonic rectangular separator, ultrasonic tumbler screen, ultrasonic airflow centrifugal screen, ultrasonic gyratory screen and so on.

Ultrasonic Screening System of Ultrasonic Vibrating Screen for Powder:

The core technical components of ultrasonic vibrating screen is the ultrasonic screening system, and the ultrasonic screening system is divided into ultrasonic power supply and transducer.

(1) Ultrasonic Control Power Supply:

Power Supply: 220V 50Hz or 110V 60HZ

Working Frequency: 36KHZ

Operating Mode: continuous/pulse

Intensity Adjustment: 50~100%

(2) Ultrasonic Transducer:

The ultrasonic transducer is very important in the ultrasonic system. Different transducers have quite different prices. The ultrasonic transducers imported from Switzerland are more expensive. But the quality is very good.

There are two kinds of installation form of ultrasonic transducer. One is built-in transducer design, and the other is the external transducer design.

Ultrasonic External Transducer Ultrasonic Built-in Transducer

Features of Ultrasonic Vibrating Screen for Powder:

1. While achieving high accuracy and high mesh screening, control the narrow range of particle size.

2. It can be used with single layer and multi-layer. A smart ultrasonic generator can use three transducers at the same time.

3. Complete screen self-cleaning function. More than 500 mesh screening, no mesh blockage, no screening efficiency attenuation.

4. It can exactly solve the screening problems of strong adsorption, easy reunite, high electrostatic, high fine, high density and light specific gravity etc.

5. Ensure that the properties of the treated material remain unchanged.

6. The screening accuracy can be increased by 1~100%, and the output can be increased by 1~10 times.

Working Principle of Ultrasonic Vibrating Screen for Powder:

The ultrasonic screening system consists of ultrasonic control power supply, ultrasonic vibrator (ultrasonic transducer) and screen mesh with energy conduction ring.

The ultrasonic screening system uses high frequency electronic frequency to convert into mechanical kinetic energy through the transducer, which makes the screen produce vibration of high frequency and low amplitude, and the vibration is transmitted through the energy conduction ring rapidly to the screen. This ultrasonic vibration can be conducted by the wire mesh of the screen, in this way, each wire mesh is in the high-frequency vibration, so it can prevent the blockage of small mesh, ensure that the screen always keep the maximum aperture ratio in the screening process. And it can also improve the liquidity of the material and make it smoothly go through the mesh screen, exactly solving the screening problems of strong adsorption, easy reunite, high electrostatic, high fine, high density and light specific gravity. Dry powder particle size can be classified to 25μm (600 mesh).

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!