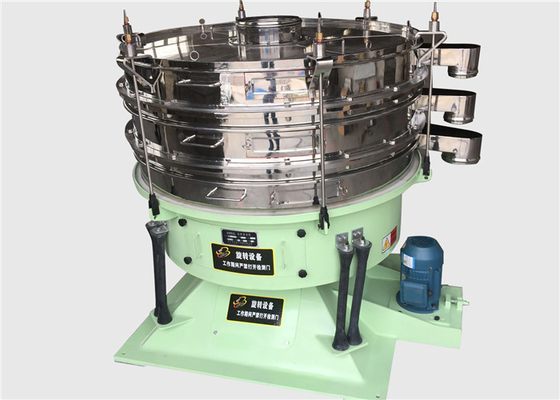

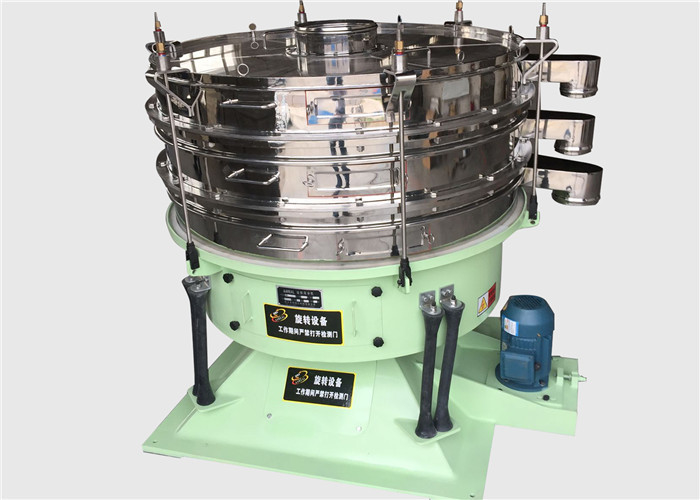

Advantages of Large Output and High Accuracy Tumbler Screening Machines for Sodium Chloride:

1. Screening process that goes gentle on the material being screened

2. Up to 6 decks and 7 particle size ranges; screen surface area/deck: 0.28–6.40 m2

3. Throughput of up to 40 t/h

4. Tumbling motion can be adjusted in a continuously variable manner with RATEX system

5. Features internal seals, gas-tight up to 50 mPa

6. High grading accuracy of up to 99%

Important Information About Large Output and High Accuracy Tumbler Screening Machines for Sodium Chloride:

| Motion |

involute spiral motion |

| Screening Accuracy |

upto 90%~99.9% |

| Diameter |

600mm, 800mm, 1000mm, 1200mm, 1500mm, 1600mm, 1800mm, 2000mm, 2300mm, 2600mm etc. |

| Mesh Cleaning Method |

bouncing ball cleaning, ultrasonic cleaning, brush cleaning, air cleaning, ultrasonic air cleaning, air brush cleaning |

| Screen Structure |

whole adhesive screen, or splicing segmented screen etc. |

| Layers of Screen |

1~5 layers of screen |

| Diameter |

600mm, 1000mm, 1200mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2100mm, 2300mm, 2600mm, 2900mm etc. |

| Advantages |

soft rock screening will not destroy the particles original structure of the material and not easy to produce static electricity |

| Optional |

quick clamps, pneumatic lifting devices etc. |

| Application |

can be used for material that is flammable, explosive and easy to generate static |

| Motor Brand |

Siemens, ABB, BEGEMA etc. |

| Surface Treatment |

polishing, sandblast, paint spraying etc. |

Application of Large Output and High Accuracy Tumbler Screening Machines for Sodium Chloride:

1. Food industry: starch, milk powder, yeast powder, sugar, salt, alkali, gourmet powder, pollen, food additive, bean milk, juice etc.

2. Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

3. Abrasive material and ceramic industry: abrasive, refractory material, slurry, building sand, mica, alumina, etc.

4. Chemical industry: resin pigment, grease, paint, medicine, palette, etc.

5. Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!