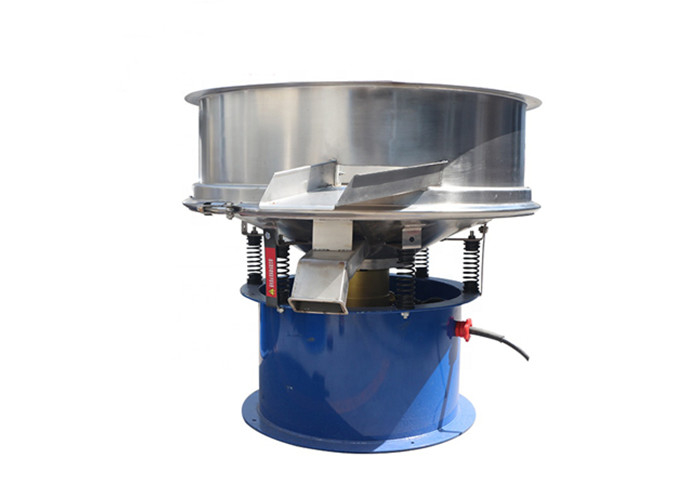

Circular Sieve Separator Machinetumbler Sifter For Paper Making Liquid

Introduction of Circular Vibrating Filter Screen Separator for Paper Making Liquid:

The Circular Vibrating Filter Screen Separator for Paper Making Liquid is mainly used for ceramic glaze, or ceramic slurry filtration to remove impurities. So it is also known as the ceramic glaze filter sieve or ceramic slurry screen machine.

Working Principle of Circular Vibrating Filter Screen Separator for Paper Making Liquid:

We adopt the new type vertical motor which can make the movement into the 3-D movement: i.e.: horizontal, vertical and incline movement and then pass the movement to the screen surface. While adjusting the phase angle of hammers at upper and lower ends of motor, the movement path of material on the screen surface can be changed.

| Center of Gravity Angle |

Purpose |

Effect |

| 0° |

rough classification |

the raw material flows from the center line to the circumferential direction |

| 15° |

general screening |

start the vortex motion |

| 45° |

precision grading |

the longest vortex motion |

| >90° |

special purpose |

raw materials concentrate to the center |

Purpose of Circular Vibrating Filter Screen Separator for Paper Making Liquid:

1. Solid-liquid separation: this kind of device can be used in single, double; can be very effective for dealing with solid and liquid mixture rapidly for solid-liquid separation and filters to filter out different mesh material.

2. Removal of Impurity: it could remove a lot of liquid fraction of miscellaneous materials of different sizes, and separated fast.

3. The filter is mainly used for the ceramic slurry filtration initial time. And now, it’s widely used for the high-throughput filtration.

Characteristics of Circular Vibrating Filter Screen Separator for Paper Making Liquid:

1. Adopting the self-developed "z" frame and single-layer network structure, the malady of the friction between the traditional double-layer network is eliminated, and the life span is extended by two to three times, and it is convenient and easy to change the net. It only takes 3~5 minutes.

2.Large amount of processing, and the contact part of raw materials is made of stainless steel 304, 316L, which is beautiful in shape.

3. Adopt the international brand Europe force wolong vibration motor, has the noise low, small volume, light weight, the power consumption small, the overload ability is strong, the appearance is fine and so on the characteristic, belongs to a new generation environmental protection product.

Technical Parameters of Circular Vibrating Filter Screen Separator for Paper Making Liquid:

| Model |

Power |

Effective Diameter |

Largest Vibration Force |

| AY-800 |

0.55 KW |

800 mm |

8000 N |

| AY-1000 |

0.75 KW |

970 mm |

10000 N |

| AY-1200 |

1.1 KW |

1170 mm |

15000 N |

Note: The above data are for reference only.

Application of Circular Vibrating Filter Screen Separator for Paper Making Liquid:

1. Chemical industry: paint, coating, bleach, etc.

2. Environmental protection: garbage, human waste, urine, waste oil, food waste water, waste water processing, etc.

3. Pharmaceutical industry: traditional Chinese medicine slurry, western medicine slurry, pharmaceutical intermediates, etc.

4. Paper industry: coating coating, white clay mud, black and white liquid, waste liquid, paper making liquid, wastewater recycling, etc.

5. Ceramic industry: ceramic slurry, ceramic glaze, etc.

6. Pollution treatment: wastewater, waste oil, pig drying urine, dyeing and finishing wastewater, etc.

7. Food industry: soy sauce, vinegar, soybean milk, fruit juice, pineapple juice, rice wine, rice wine, bean dregs, yeast solution, beverages, etc.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!