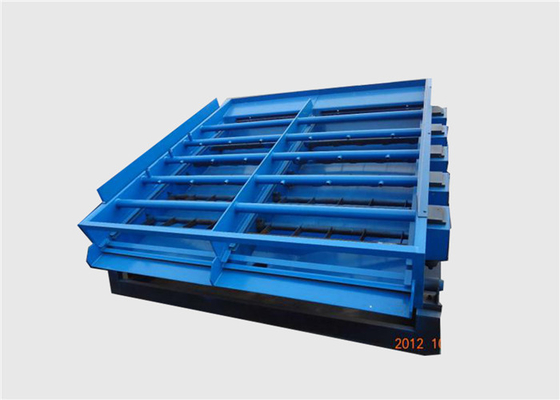

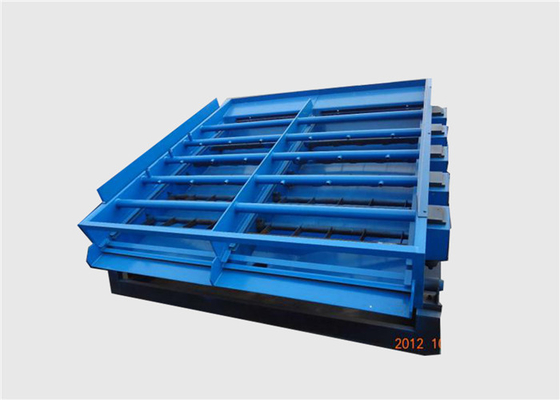

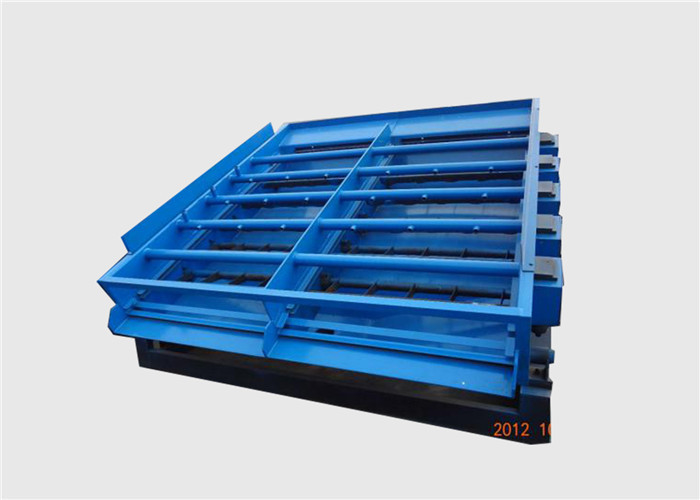

Overview of High frequency Wire Mesh Vibrating Fine Screen for Coal Slime Dewatering:

High frequency Wire Mesh Vibrating Fine Screen for Coal Slime Dewatering is a new type of vibration screening equipment. Only the screen mesh vibrates, and the screen box does not vibrate.

This sieve vibrating screen machine can be widely used in chemical and compound fertilizer industry, ore dressing (iron ore, quartz sand, kaolin etc.), dewatering (coal slime dewatering, tailings dry dewatering, gold ore powder carbon recovery and dehydration etc.), dry material sieve and so on.

With small dynamic load, low power consumption, high screening efficiency and large processing capacity.

Features of High frequency Wire Mesh Vibrating Fine Screen for Coal Slime Dewatering:

1. The sieve surface vibrates, while the screen box does not.

2. The screen is composed of three layers of woven mesh. And the composite screen has a high opening rate. The screen can also use single layer mesh of coarse silk.

3. No mesh blocking. With strong sieve surface self-cleaning ability, high screening efficiency and large processing capacity.

4. Saving energy and protecting environment.

5. Minimal dynamic load.

6. It is very suitable for screening of fine particle materials.

7. Safe to use, easy to maintain, small footprint.

8. The screen installation angle can be easily adjusted to meet the nature of materials and different screening operations.

Technical Parameters of High frequency Wire Mesh Vibrating Fine Screen for Coal Slime Dewatering:

| Model |

Screen Area (m²) |

Working Frequency (Hz) |

Screen Slope

( °)

|

Power

(Kw)

|

Weight (Kg) |

Reference Size (including maintenance platform)

L*W*H (mm) |

| 2ZWS1518-D-II |

2×2.7 |

50 |

20;25;30;35 |

1.8 |

4300 |

3603*3824*2856 |

| 3ZWS1518-D-II |

3×2.7 |

50 |

20;25;30;35 |

2.7 |

5500 |

4348*3824*3390 |

| 2ZWS2018-S-II |

2×3.6 |

50 |

20;25;30;35 |

3.6 |

5300 |

3649*4456*2830 |

| 3ZWS2018-S-II |

3×3.6 |

50 |

20;25;30;35 |

5.4 |

8000 |

4348*4456*3300 |

| 4ZWS2018-S-II |

4×3.6 |

50 |

20;25;30;35 |

7.2 |

10900 |

4829*4450*3900 |

| 2ZWS2020-S-II |

2×4.0 |

50 |

20;25;30;35 |

3.6 |

5500 |

3750*4456*2814 |

| 3ZWS2020-S-II |

3×4.0 |

50 |

20;25;30;35 |

5.4 |

8400 |

4575*4456*3305 |

| 4ZWS2020-S-II |

4×4.0 |

50 |

20;25;30;35 |

7.2 |

11500 |

5220*4456*3996 |

| 2ZWS2418-S-II |

2×4.32 |

50 |

20;25;30;35 |

3.6 |

5700 |

3649*4766*2856 |

| 3ZWS2418-S-II |

3×4.32 |

50 |

20;25;30;35 |

5.4 |

8600 |

4348*4766*3297 |

| 4ZWS2418-S-II |

4×4.32 |

50 |

20;25;30;35 |

7.2 |

11700 |

4829*4766*3832 |

| 2ZWS2420-S-II |

2×4.8 |

50 |

20;25;30;35 |

3.6 |

5900 |

3750*4766*2835 |

| 3ZWS2420-S-II |

3×4.8 |

50 |

20;25;30;35 |

5.4 |

9000 |

4575*4766*3300 |

| 4ZWS2420-S-II |

4×4.8 |

50 |

20;25;30;35 |

7.2 |

12300 |

5220*4766*3900 |

Working Principle of High frequency Wire Mesh Vibrating Fine Screen for Coal Slime Dewatering:

The wire cloth vibrating screen machine is driven by an electromagnetic exciter. The electromagnetic force makes the vibrating arm placed under the sieve surface torsion and swing through a force transmission bolt, a main vibration spring, a hinge spring, a vibration rod and a vibration shaft. A vibrating cap is provided on the upper end of the vibrating arm to support the screen to generate vibration. The vibration system works in a near-resonance state, and the power required for screening is achieved with less power. The vibration intensity of the screen surface is 8-10 times the gravity doubling speed, which is 2-3 times that of the general vibration screen. High screening efficiency and large processing capacity.

The multi-layer screen machine is divided into single channel and double channel. Each layer of screen in single channel consists of four groups of vibration system and one group of exciters. Each layer of dual-channel screener consists of eight sets of vibration systems and two sets of exciters, which are distributed on the left and right sides of the screen box. The rated power of each group of exciters is 900W, which will cause 50Hz high frequency vibration on the screen surface. The screen surface vibration parameters are controlled by the control cabinet. The vibration system has the function of instantaneous strong vibration to clean the screen and reduce the mesh blockage.

Electromagnetic Vibrating Mesh Screen Machine

Motor Vibrating Mesh Screen Machine

Application of High frequency Wire Mesh Vibrating Fine Screen for Coal Slime Dewatering:

The vibrating wire cloth screen machine is widely used in the pulp screening in the processing of ferrous and nonferrous minerals, products dewatering in the coal washing process, and products grading in the chemical industry. It is mainly used for dry and wet screening, classification, dewatering, desilting, coarse separation of fine-grained materials. And this sieve machine have a good screening effect.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!