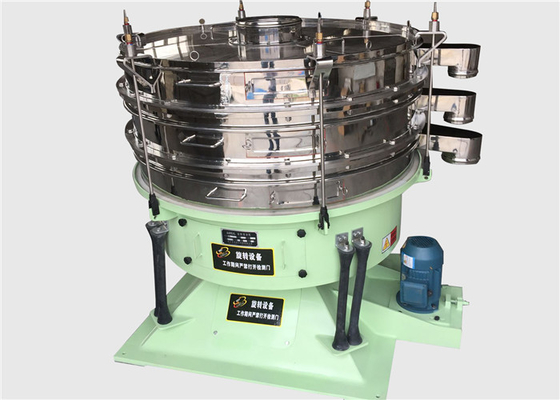

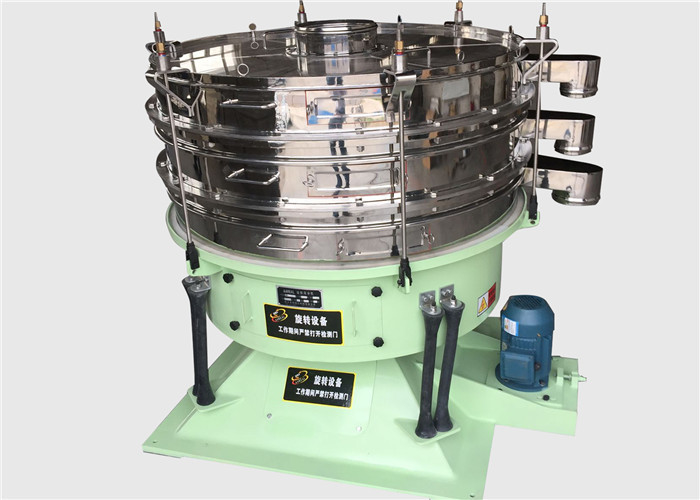

PVC PowderTumbler Screening Machine Three Dimensional

Overview of Tumbler Screening Machine for PVC Plastic Powder:

Tumbler fine sieve is a high powered sieving machine used by manufacturers from different industries to produce large outputs of light powder particles with high capacity by continuous low-density sieving.

Unlike a typical vibratory or gyratory screening machine, the tumbler screening machine incorporates a unique three-dimensional tumbling motion providing the gentlest screening possible. This motion prevents delicate, friable material from being broken resulting in less undesirable fine generation and dust levels. Even the most difficult materials, which tend to blind screens, are screened efficiently by utilizing the proper anti-blinding systems including motor driven brushes and/or air knives that are unique to tumbler type screening machines.

The tumbler screening machines are used for bulk material grading, safety screening, and dedusting in all industrial sectors. They are particularly well-suited to the fine and extremely fine screening of dry bulk materials and precise grading with up to 6 particle sizes.

Manual sieving is the process of using your hands and a mesh strainer to separate unwanted elements from the fine powder particles. What the Tumbler Fine Sieve does is the mechanical equivalent of that. Artificial sieving is done by effective processing and simulation of fine and ultra-fine powders and other materials that are difficult to characterize and shift. Efficient and precise separation of particles is the best principle for producing large quantities of sieved materials in a short period.

Working Principle of Tumbler Screening Machine for PVC Plastic Powder:

The tumbler screener utilizes the humanoid screening principle. To imitate the movement of artificial screening action and do three-dimensional circular motion, skillfully combine the sieving (planar circular motion) and winnowing (upward parabolic motion), establish horizontal and throwing three-dimensional tumbling movement, make the material in the screen surface appear involute spiral movement. The material takes a relatively long distance across the relative area, and the landing screen time of the material is more than 85%, improving the screen through rate. The screening accuracy is as high as 90%~99%, increasing the yield.

According to the physical properties of the material and the different screening requirements of customers, we can adjust the independent and adjustable rotate speed, eccentricity, radial force, tangential force, so as to change the material stay time on the screen surface and the moving route to achieve the best screening effect.

1. Basic rotary motion is similar to manual screening. Eccentricity is adjustable from 25 to 40mm, and low-speed v-type belt drive is adjustable from 120 to 360rpm.

2. The residence time of each product can be adjusted in the direction of the driving axis by the radial and tangential angles of the swing screen.

3. Hence, it establishes horizontal and projectile 3D tumbling motion. Materials are evenly dispersed from the center to the outer edge on the entire screen surface. So, fine particles are completely finished the whole screening process.

4. This process is repeated between each screen layer.

Important Information About Tumbler Screening Machine for PVC Plastic Powder You Won't Miss:

| Motion |

involute spiral motion |

| Screening Accuracy |

upto 90%~99.9% |

| Mesh Cleaning Method |

bouncing ball cleaning, ultrasonic cleaning, brush cleaning, air cleaning, ultrasonic air cleaning, air brush cleaning |

| Screen Structure |

whole adhesive screen, or splicing segmented screen etc. |

| Layers of Screen |

1~5 layers of screen |

| Diameter |

600mm, 1000mm, 1200mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2100mm, 2300mm, 2600mm, 2900mm etc. |

| Advantages |

soft rock screening will not destroy the particles original structure of the material and not easy to produce static electricity |

| Optional |

quick clamps, pneumatic lifting devices etc. |

| Application |

can be used for material that is flammable, explosive and easy to generate static |

Features of Tumbler Screening Machine for PVC Plastic Powder:

1. Up to 5 times outlet compared with common sieving machine

2. At most 6 levels separation

3. Sieving efficiency is over 95%

4. When using the silicone rubber balls, ultrasonic and other high-performance mesh-cleaning device system, the sieve aperture will not be blocked.

5. Enclosed cleaning dust, safe operation; the acceleration is 4.5 times higher than common vibrating screen.

6. Noise less than 75dB. Re-optimization is balanced, groud-based dynamic load is low.

Technical Parameters of Tumbler Screening Machine for PVC Plastic Powder:

| Model |

Screen Area (m²) |

Layers of Screen |

Motor Power (KW) |

| AM-600 |

0.28 |

1~5 |

0.25 |

| AM-1000 |

0.72 |

1~5 |

1.5 |

| AM-1200 |

1.10 |

1~5 |

1.5 |

| AM-1500 |

1.80 |

1~5 |

2.2 |

| AM-1800 |

2.30 |

1~5 |

4.0 |

| AM-2000 |

2.60 |

1~5 |

4.0 |

| AM-2300 |

3.90 |

1~5 |

4.0 |

| AM-2600 |

5.30 |

1~5 |

5.5 |

| AM-2900 |

6.40 |

1~5 |

5.5 |

Application of High Precision Rotary Tumbler Screening Machine for Food Additive:

1. Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry etc.

2. Chemical industry: resin pigment, medicine, grease, paint, palette etc.

3. Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice etc.

4. Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide etc.

5. Mechanical industry: casting sand, powder metallurgy, electromagnetic material andmetal powder etc.

BALANCE IS IMPORTANT !! Pneumatic Lifting Device

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!