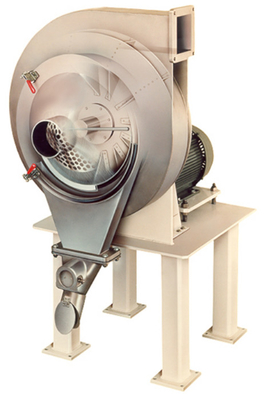

High Performance Rotary Sifter Screens Vortex Sieving Machine Blow Through Type

Overview of Air Classifier Vortex Sieving Machine:

Blow-through type high-performance vortex sieving machine is also called vortex screen, high efficiency wind screening machine, blow-through type high-performance sieving machine etc. It provides continuous dry material screening, achieving the high efficiency micron-sized accurate separation of 25µm~8500µm particles.

It is suitable for materials that are difficult to screen with traditional equipments such as vibrating screen, ultrasonic screening machine, tumbler screen etc.. For example, particles with static electricity, materials easy to agglomerate and with light specific gravity, viscous materials containing water or oil and so on. Or it can be used behind the airflow classifier to ensure that the ultra-fine powder is without large particles after the classifier.

Working Principle of Air Classifier Vortex Sieving Machine:

Blow-through type high-performance vortex sieving machine controls the particle size precisely through the screen mesh.

The powder is dispersed in the airflow and through the static screen, so it can accurately screen micron-sized powder, which can not be realized by vibration type sieving machine or air classifier.

The blow-through type high-performance vortex sieving machine has a great contribution to the diversification, high added value and high quality of all kinds of powder raw materials and products. Furthermore, for the powder with humidity, oil content and electric charge that is difficult to screen and yield can not be guaranteed, it is a professional screening machine.

Application of Air Classifier Vortex Sieving Machine:

The blow-through type high-performance vortex sieving machine can be used in food, powder metal, chemical, plastic, cosmetics, pigments, tobacco, pharmaceuticals, minerals, electronics, ceramics and other industries.

Features of Air Classifier Vortex Sieving Machine:

1. There is no blockage because of the air brush. Thus the vortex screen can sieve smoothly from the granular to the micro powder, and finally to several microns of ultrafine particles.

2. With unique working principle and excellent screen anti-blocking performance, it is almost allowed to screen any type of powders regardless of the specific gravity size, and no matter whether it has the powder properties such as adhesiveness, cohesion, coagulation, fluidity, hygroscopicity and so on, more suitable for screening lightweight and electrostatic materials. It can easily complete the spherical particle sieving that the ultrasonic screening machine can not manage.

3. Fully automatic continuous operation. It can be easily added into the grinding and pneumatic conveying production line.

4. It takes just a few minutes to realize quick screen replacement.

5. High screening accuracy, low failure rate and convenient maintenance.

6. Cover a small area. The processing capacity per unit area of screen is super strong.

7. Slight vibration, low noise, full closed structure, no dust, no pollution.

Technical Parameters of Air Classifier Vortex Sieving Machine:

| Model |

Screen Diameter (mm) |

Power (KW) |

Weight (KG) |

| APQ-18 |

458 |

4 |

230 |

| APQ-30 |

762 |

5.5 |

560 |

| APQ-38 |

965 |

7.5 |

650 |

| APQ-45 |

1145 |

11 |

820 |

Examples for Various Powders Processing of Air Classifier Vortex Sieving Machine:

| Material |

Soldering Tin |

Talcum Powder |

Powder Coating |

Toner |

Carbon Powder |

Wood Flour |

| Capacity |

APQ-18 |

30 |

100 |

50 |

70 |

50 |

70 |

| APQ-30 |

120 |

420 |

200 |

420 |

200 |

300 |

| Screen Mesh (µm) |

25 |

75 |

75 |

45 |

75 |

150 |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!